INVESTING IN NEW CAPABILITIES

LEVERAGING EMERGING TECHNOLOGIES FOR INNOVATIVE OPPORTUNITIES.

Our customer-focus approach enables Ryder to evaluate early-stage innovative technologies to advise our customers about their value and stay at the market forefront. We have strong history in leveraging emerging technologies that help make our business and, ultimately, our customers’ businesses more efficient and competitive. As disruptive trends continue to reshape the logistics and transportation industry, it is our responsibility to help our customers adapt to this rapidly evolving marketplace. Through our guidance, our customers save time, money, and resources, while addressing their business’s environmental impact.

Our Approach

Ryder leverages cross-functional leadership to monitor and respond to trends impacting our business, industry, and by extension, our customers. As part of our annual strategic planning process, our Board reviews emerging and disruptive trends in our industry. To that end, in 2018, we launched our New Product Strategy organization with the goal of creating a more centralized and cohesive approach to the development of new products. Since its launch, we are working with start-up companies, venture capitalists, start-up accelerator groups, academia, and other disruptors to ensure Ryder is engaged with the newest players, models, and emerging technologies in our industry.

In October 2020, Ryder launched RyderVentures, a corporate venture capital fund that is targeting $50 million in investments over the next five years. Through RyderVentures, we are investing in and partnering with start-up companies enabling the future of logistics. Our focus is on start-up companies that are tackling disruptions related to e-commerce, next generation vehicles, asset sharing, and data analytics. By launching RyderVentures, we are able to further identify future partners, help develop new technologies and business models, and accelerate advancements in the logistics and transportation industries that will better serve us and our customers. Our goal is to identify new technologies at an earlier stage, ramp up innovation efforts to get ahead of growing demands, and accelerate market-adoption of these solutions.

As we continue to integrate the disruptive trends into our strategic planning, we aim to develop and leverage technologies to tackle these disruptions:

E-Commerce

Within the United States and Canada, e-commerce orders and online revenues increased dramatically. Prior to the COVID-19 pandemic, it was estimated that e-commerce sales would account for approximately half of all retail sales by 2040. During the COVID-19 pandemic, Ryder has experienced an increased demand for our services including last-mile delivery and e-commerce fulfillment as consumers around the globe have shifted to online shopping to avoid crowds. Our e-commerce fulfillment solutions help our customers meet the increased online purchasing, expedited delivery expectations, and demand for real-time visibility. We are focused on providing innovative services and enabling our customers to better execute their e-commerce solutions while responding to evolving consumer and market demands.

The growth in e-commerce most directly impacts our work with our Supply Chain Solutions (SCS) customers, who rely on Ryder to manage their distribution network with omnichannel fulfillment strategies. Our expansive footprint, strategically placed fulfillment centers, logistical expertise, and fleet optimization services provide holistic solutions for the growing market. As the e-commerce market continues to expand, Ryder is working on initiatives to enhance our service offerings. We also continue to partner with third parties to increase scale and further maximize the value provided to our customers.

Highlight Story: IDENTIFYING AND FUNDING THE FUTURE OF LOGISTICS

RyderVentures makes its first investment in SmartHop, a Miami-based tech-for-trucking startup leveling the playing field for small fleets and owner-operators. The funds from RyderVentures will be used by SmartHop to help grow their network, enhance their product, and boost hiring to meet the evolving needs of the trucking market segment that is six trucks or fewer. SmartHop’s AI-powered, full-service dispatching platform is designed to help reduce operational costs, provide access to broker networks, streamline load booking, and navigate the spot market. By helping smaller companies and owner-operators identify the best opportunities for productivity and reduce empty hauls, there will be potential gains in environmental and industry efficiencies.

Next Generation Vehicles

Changing regulations, evolving demographics, and a growing interest in sustainability are driving demand for autonomous vehicles (AVs) and alternative fuel vehicles (AFVs). Ryder is committed to equipping our fleet with the latest vehicle technologies. Together with our clients and partners, we are leading the industry toward adoption of AVs as well as low-carbon, AFVs. While the timeline for AVs is unclear, Ryder remains steadfast in building the strategies and partnerships that will enable our customers to receive the benefits of advancing safety technologies today. Ryder continues to invest and work with AV providers to develop deployment strategies of future technologies.

Asset Sharing

As the world of the sharing economy continues to mature and evolve, Ryder has the opportunity to utilize technologies that improve efficiencies across our value chain including the sharing of vehicles and freight among customers. Our Chief Marketing Officer manages Ryder’s asset sharing initiatives. By increasing customer access to vehicle- and freight-sharing platforms, customers can realize value on their underutilized assets. By developing new, innovative products and concepts like these, we are able to provide opportunities for customers to test solutions not currently available in the marketplace. In addition to driving efficiency, these solutions benefit the environment by optimizing available equipment and freight capacity.

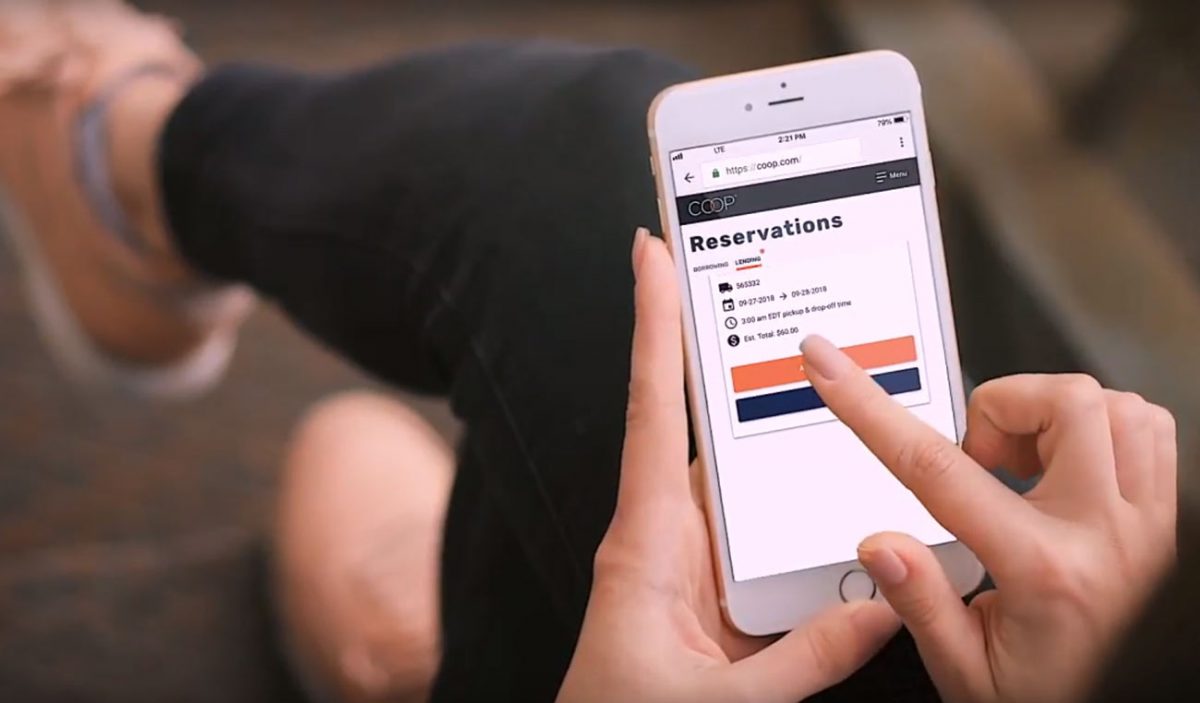

Highlight Story: Truck Sharing with COOP™

Ryder introduced COOP—the first ever peer-to-peer digital platform for commercial vehicle sharing—in 2018. COOP enables customers to monetize their underutilized truck capacity within their fleet by renting vehicles to business peers, which increases optimization and useful life of equipment. Through COOP, there is a wide selection of equipment available for customers to utilize including Workhorse electric vehicles. We offer the service to business owners in Georgia, Florida, North Carolina, Tennessee, Texas, and southern California. COOP is Ryder’s initial entry to the sharing economy, which has been credited with generating sustainability and economic benefits. We have established over 3,000 accounts and have generated more than 90,000 rental days on the platform.

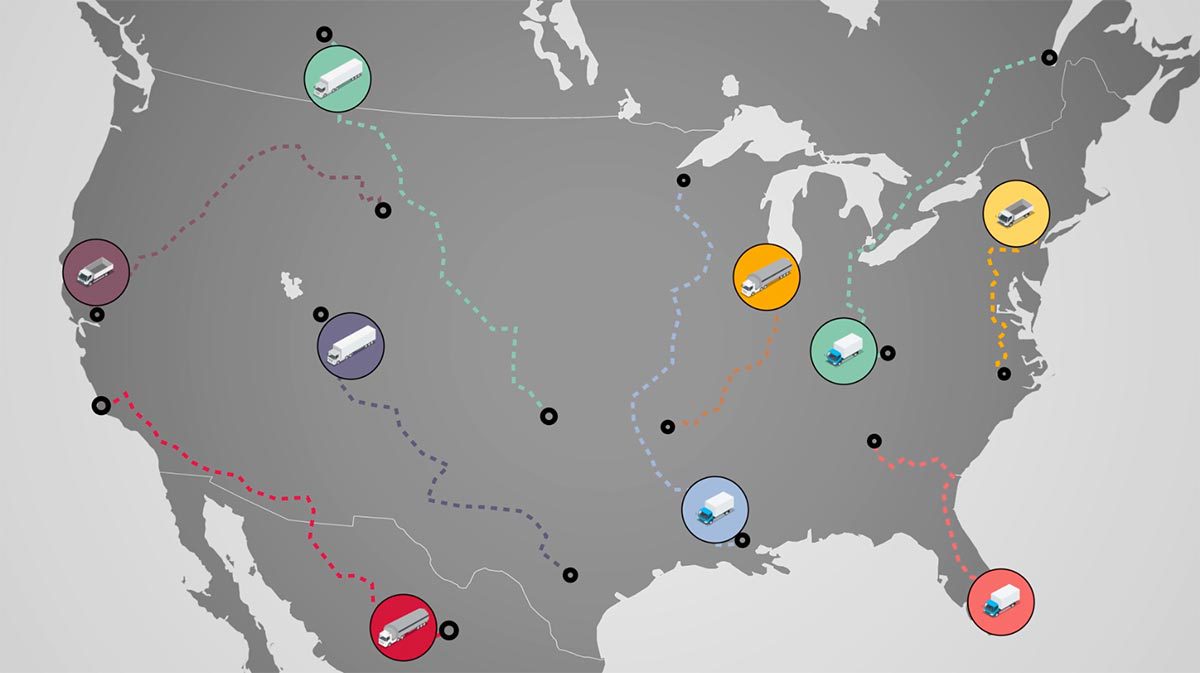

Highlight Story: RyderShare™

RyderShare is an end-to-end, digital platform that allows everyone across a company’s supply chain to benefit from real-time visibility and collaboration into orders, inventory, and shipments. This cloud-based platform enables customers to reliably see and act on the delivery of their products, which includes the ability to share transportation assets and broker freight as needed. With actionable visibility, tracking, alerts, and analytics, our customers can save time, money, and resources.

Big Data

Technological advances have improved the ability to collect, analyze, and interpret data. At Ryder, we are adopting these technologies to enhance our services, create new solutions, and increase our organizational efficiencies. By equipping our drivers, technicians, and fleet with innovative tools, we are increasingly using data analytics to better understand our business and our customers’ businesses so we can serve them better. Vehicle telematics systems provide a foundation for a deeper understanding of our fleet—from reviewing speed and idling time to compliance with the electronic logging device (ELD) mandate. DriveCam technology, advanced safety features, and Ryder Safety NET—our Incident Management System—strengthen our proactive safety management, enabling the identification of collision and injury root causes and implementation of tailored trainings and coaching. Moving forward, we will continue to leverage data and connectivity in our logistics and transportation solutions, such as route and load optimization, vehicle maintenance planning, and reducing our customers’ environmental impacts.

Digitizing the Supply Chain

By embracing digitization and the power of the cloud, we continue to improve our agility and increase efficiencies for our customers through communication and collaboration. Ryder’s strategy to lead the change by forming strategic partnerships and piloting new technologies create customer-centric solutions that drive impact. It is how we provide companies with the visibility needed to proactively manage exceptions in the movement of goods through the supply chain. And, how we connect multiple people to collaborate in real-time to solve in minutes, what previously took days or weeks to fix.

We are accomplishing this through technologies like RyderShare™ and RyderGyde™, which seamlessly integrate with our best in class warehouse management and transportation management systems. In doing so, it digitizes supply chains by collecting data in one place and combines it with consumer data, so it can be turned into business intelligence and used for predictive analytics and closed-loop planning. Through the integration and implementation of innovative systems and tools that drive actionable analytics and data, we create a culture of continuous improvement. Technologies such as robotics, augmented reality, artificial intelligence (AI), analytics, and cognitive technologies are creating an environment capable of more informed decision making. It has led to strategically locating e-commerce fulfillment hubs to make two-day delivery possible. Greater visibility enables all within the supply chain to anticipate changes in timing and adapt quickly to mitigate delays. This ability has become essential as consumers demand further insight into tracking systems and expect prompt updates on deliveries.

LEAN Operations

Ryder’s supply chain outsourcing offerings incorporate LEAN methodologies to deliver efficiency. These practices improve quality and productivity by reducing cost and waste in all aspects of supply chain management and operation, from procurement of raw materials to shipment of finished goods. By strategically avoiding types of waste—both physical and in-process—we meet our customers’ expectations faster and more efficiently. The five key principles of a LEAN organization are:

People involvement

From the C-suite to the loading dock, all employees work together as a team to eliminate waste, reduce cost, and provide greater value for customers.

Built-in quality

Supply chain processes must be performed correctly to facilitate the smooth flow of goods from point to point so orders can be filled correctly, completely, and on time. This leads to higher levels of customer satisfaction and lower transportation costs.

Standardization

Employees in a LEAN facility are trained in documented best practices and expected to follow them. Standardization makes it easy to calculate the time and resources needed to complete specific work processes and provides the foundation for continuous improvement.

Short lead times

The shorter the time between a customer placing and receiving an order, is a LEANer supply chain. Short lead times free up cash and make it available for other uses that would otherwise be tied-up in “safety stock” inventory.

Continuous improvement

Finding ways to remove waste and improve quality becomes the responsibility of every employee in a LEAN facility, leading to an ongoing stream of small gains that add up to big improvements over time.

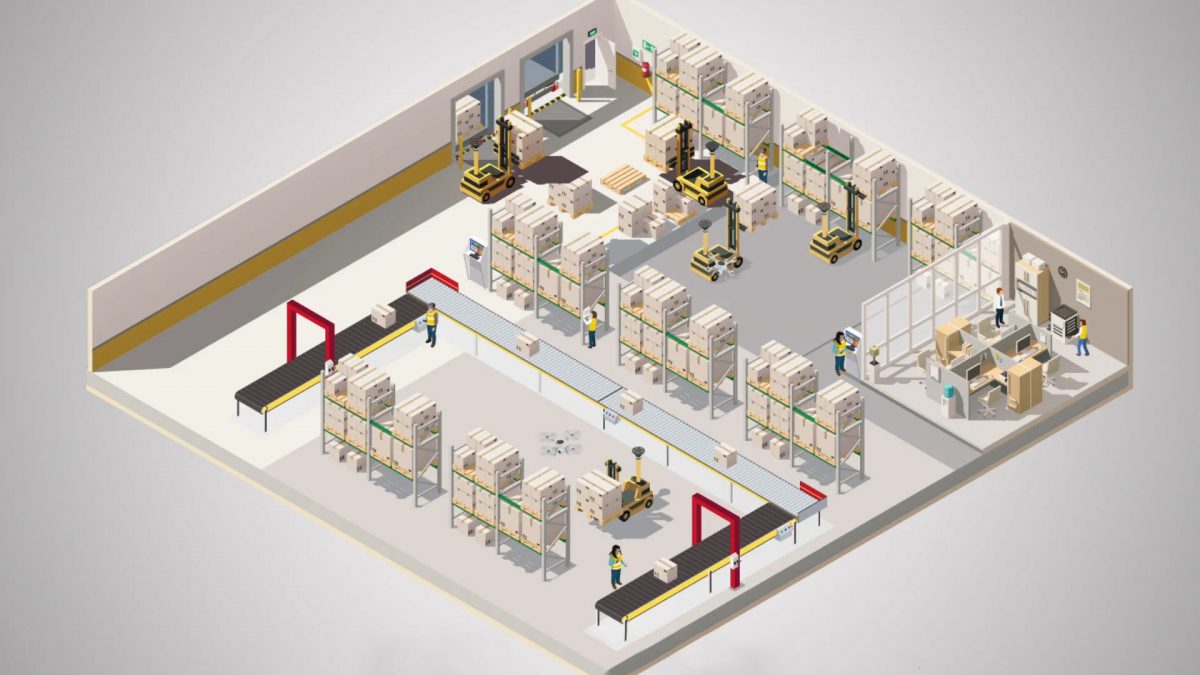

Smart Warehousing

Beginning in 2017, we started piloting technologies in our warehouses that look to improve efficiencies, offering our customers a transformational digital supply chain solution that improves processes and focuses on speed-to-market. Our automation team evaluates all new technologies coming to market and matches them against new and existing warehouse profiles to determine the best methods for deployment in order to drive value for our customers. Ryder has identified the technologies below as definitive benchmarks of an effective smart warehouse, and each area of innovation is already delivering significant improvements for customers:

- Robotics & Automation

- Autonomous Mobile Robots have shown to increase productivity of pickers by over 30% by reducing travel and providing an optimized hands-free environment.

- Autonomous Fork Trucks have improved inventory accuracy and safety, while reducing costs by 20-30%.

- Automated Storage & Retrieval Units have increased space utilization by 50% and doubled pick efficiency.

- Sensors – Material Handling Equipment and Personnel Telematics solutions have been implemented throughout the Ryder network improving operator safety and increasing equipment utilization by 10-20%.

- Wearables – Ryder deployed solutions such as smart glasses and voice picking technology for improved efficiency approaching 20%.

- Analytics – By displaying real-time performance and output results to the employees on the floor, we have seen core process productivity increases of up to 24%.

To learn more about our operational efficiencies, see the Environmental Stewardship section of this report.

Highlight Story: RyderGyde™

Ryder launched in 2018 the first fleet management mobile application in the industry, RyderGyde, for our Fleet Management Solutions (FMS) customers. Using the app, customers can schedule maintenance in under a minute, access fuel rates (from Ryder and third parties), access rental and used vehicle sales, enable fuel tax reporting, and track mileage. We developed the app in response to increased feedback that customers prefer digital interaction to decrease transaction time and expand efficiencies. RyderGyde helps our customers manage their fleet, ensure timely maintenance, and interact with Ryder more easily. To date, more than 50,000 customers have utilized RyderGyde. We continue to release customer-facing solutions and enhance features for our customers and business segments.